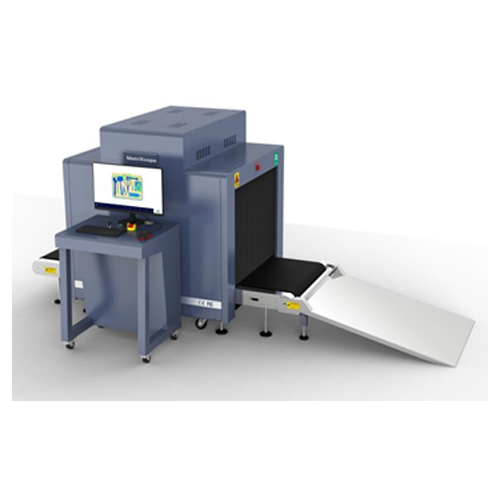

Universal X-RAY Equipment Matrixcope MTC-8200XPRO

Matrixcope MTC-8200XPRO has a wide range of inspection fields and is usually used in the internal structure inspection of electronic components.

Product Documents

Downloads

Overview of universal x-ray equipment Matrixcope MTC-8200XPRO

Matrixcope MTC-8200XPRO inspection equipment has a wide range of applications, commonly used in the internal structure inspection of electronic components, common bubble voidage measurement, electrical short-circuit, break-circuit, weld defects, less welding, missing welding of the welding spot, foreign matters and cracks inside the internal part, etc. It has easy maintenance, long service life, simple operation, as well as reduce the training of operators, high inspection accuracy, allows a maximum 60-degree viewing angle to detect samples, etc

Application:

- Router 4. Lithium battery

- Wire harness 5. Wires

- Monitor 6. Fuse

Specifications of universal x-ray equipment Matrixcope MTC-8200XPRO

|

PHYSICAL SPECIFICATIONS |

|

| X-Ray tube type | Enclosed type |

| Spatial resolutiaon | 5um |

| Light tube voltage | 90KV (Optional 100KV、130KV) |

| Light tube current | 200uA |

| Magnification | Optical magnification 250X, system magnification 1000X |

| Digital flat panel detector resolution | 1536*1536 px |

| Digital flat panel detector density value | 16bit (655) |

| Image speed | 20 (FPS) |

| Detector rotation angle | 60° |

| Stage size | 540*540mm |

| Detection speed | 360° |

| X-Y strokee | 800*1000mm |

| Examination range | 0.02-45cm2 |

| Machine size | 1100*1360*1750mm(L*W*H) |

| Machine weight | 950KG |

| Operating system | WINDOWS 10 |

| Power supply/power | AC110-220V 50-60HZ 1200W |

| Radiation safety test | <1 uSV/H |

| Stage movement | Automatic / manual |

| CE Certificate | Yes: STE23112101S |

| State immunity | Yes |

Functional Advantage:

| Function | Advantage |

| CNC program: Automatically detect batch of different samples’ locations | Automatically ON / OFF X-Ray tubes detect batch of samples |

| Array function: Automatically detect batch of samples with fixed position and same spacing | With high-stability and high-precision X-Ray tube |

| Bubble measurement: measure the bubble size, cavity rate, tin climbing height with one button | High definition digital X-Ray detector |

| Length and width measurement: the length and width of the measured inspection area | The stage can place a large number of samples of various sizes |

| Visual navigation interface: accurate positioning, accurate displacement from x – y with joystick | The stage can do 360° rotation to detect sample |

| Simulated color: to better observe and detect the image | Can do 60° tilt observations |

With its exceptional microstructure inspection capabilities and high precision, the Matrixcope MTC-8200XPRO is the ideal solution for manufacturers and quality control professionals in the electronics industry. Whether you’re detecting bubble void rates, short or open circuits, insufficient soldering, or internal cracks and foreign objects, this advanced system delivers reliable, detailed results.

Contact the official distributor of Matrixcope products today to learn more and receive a customized quote.

? Discover more cutting-edge solutions at: https://matrixcope.com/

Specifications of universal x-ray equipment Matrixcope MTC-8200XPRO

|

PHYSICAL SPECIFICATIONS |

|

| X-Ray tube type | Enclosed type |

| Spatial resolutiaon | 5um |

| Light tube voltage | 90KV (Optional 100KV、130KV) |

| Light tube current | 200uA |

| Magnification | Optical magnification 250X, system magnification 1000X |

| Digital flat panel detector resolution | 1536*1536 px |

| Digital flat panel detector density value | 16bit (655) |

| Image speed | 20 (FPS) |

| Detector rotation angle | 60° |

| Stage size | 540*540mm |

| Detection speed | 360° |

| X-Y strokee | 800*1000mm |

| Examination range | 0.02-45cm2 |

| Machine size | 1100*1360*1750mm(L*W*H) |

| Machine weight | 950KG |

| Operating system | WINDOWS 10 |

| Power supply/power | AC110-220V 50-60HZ 1200W |

| Radiation safety test | <1 uSV/H |

| Stage movement | Automatic / manual |

| CE Certificate | Yes: STE23112101S |

| State immunity | Yes |

Related products

The MatriXcope MTC-XR86 is a high-performance X-ray baggage scanner that embodies the cutting-edge technology and innovation synonymous with Matrixcope, a premier security solutions brand from the USA.

The MatriXcope MTC-XR64PRO luggage X-ray scanner utilizes an advanced X-ray imaging system, integrating semiconductor detectors, digital image processing technology, and computer image display technology.

In today's security-conscious world, the need for efficient and reliable baggage scanners is paramount. Let's delve into the features of an advanced X-ray baggage scanner that combines cutting-edge technology with safety and environmental considerations: