High Precision X-Ray Counting Matrixcope MTC-4200XPRO

Matrixcope MTC-4200XPRO is mainly used for high-speed counting of reel materials in the SMT industry. It can count 4-17 inch Tape Reel/JEDEC reel/IC moisture sensitivity package and other materials.

Product Documents

Downloads

Overview of high precision x-ray counting Matrixcope MTC-4200XPRO

Matrixcope MTC-4200XPRO is mainly used for high-speed counting of reel materials in the SMT industry. It can count 4-17 inch Tape Reel/JEDEC reel/IC moisture sensitivity package and other materials. Material types include all resistance and capacitance materials and IC materials. Use X-Ray imaging technology to detect production materials and obtain image information for high-speed counting, and connect equipment data information with the customer’s MES system.

Technical specifications high precision x-ray counting Matrixcope MTC-4200XPRO

|

PHYSICAL SPECIFICATIONS |

|

| Tube type | Enclosed type |

| Spatial resolution | 30μm |

| Tube voltage | 50kV (no more than 80kV) |

| Tube current | 0.01-1mA |

| Image taking type | Flat-panel Digital |

| Imaging precision | 139μm |

| Image size | 427*427mm |

| Dpi | 3072*3072px |

| Image taking speed | 5 EDS/s |

| Code reading pixels | 20 million / inch |

| Miscalculation rate (0201) | ≤0.01% |

| Accuracy | 99.99% (0201 as an example) |

| Minimum part size that can be detected | 01005 |

| Record keeping requirements | Save by day, no capacity limit, TXT.CSV.XLS |

| Operating system | WINDOWS 11 |

| Power supply | AC110-220V50-60HZ |

| Power | 1200W |

| Radiation safety test | <1 uSV/H |

| Repeatability test | ≥2.0sigma |

| CYCLE TIME | ≤10s / time |

| Material counting speed | 6-10 S / 4 reels (CHIP 0201) |

| Max diameter of the material reel | 430mm(4-17INCH) |

| Max height of the material reel | 1-92mm |

| Max weight of the material reel | ≤10kg |

| Machine size | 730*1460*1960mm(L*W*H) |

| Machine size (including printer) | 950*1460*1960mm(L*W*H) |

| Machine weight | 450kg |

| Stage movement mode | Auto-mode |

| CE Certificate | Yes: STE23112103S |

| State immunity | Yes |

| Radiation Safety Permit | Yes: Guangdong Environmental Radiation Safety Permit [B0640] |

Function Interpretation:

Functional Advantage high precision x-ray counting Matrixcope MTC-4200XPRO

|

Functions: |

Inductive printing of material labels |

| Can count 4 material reels at once, or one single reel | |

| Intelligent code reading (optional) | |

| Data management | |

|

Features: |

0201 as an example, the identification accuracy is as high as 99.99% |

| Can count special-shaped materials, bulk materials, or multiple reels | |

| Auto fluoroscopic imaging, auto analysis, auto counting | |

| No operating table, equipped with a touch industrial monitor to save space | |

| Read all labels of the material reel and output to MES | |

| Connect to MES, and data updated automatically | |

|

Advantages: |

Different material reels can be counted and images can be captured at the same time. Automatic numbering/counting |

| 6-10 seconds for a quick counting | |

| Reduce the number of processes, shorten process routes, and improve efficiency | |

| Comes with its own database and provides query and printing |

With near-perfect counting accuracy, fast processing speed, and seamless integration with MES systems, the Matrixcope MTC-4200XPRO is the ideal solution for modern SMT production lines. This device not only minimizes inventory errors but also streamlines the production process, enhances productivity, and improves warehouse management efficiency. If you are looking for an advanced, reliable, and easy-to-integrate reel counting solution, the Matrixcope MTC-4200XPRO is your top choice.

Learn more at: https://matrixcope.com/ – A leading brand in high-precision X-Ray counting technology.

Technical specifications high precision x-ray counting Matrixcope MTC-4200XPRO

|

PHYSICAL SPECIFICATIONS |

|

| Tube type | Enclosed type |

| Spatial resolution | 30μm |

| Tube voltage | 50kV (no more than 80kV) |

| Tube current | 0.01-1mA |

| Image taking type | Flat-panel Digital |

| Imaging precision | 139μm |

| Image size | 427*427mm |

| Dpi | 3072*3072px |

| Image taking speed | 5 EDS/s |

| Code reading pixels | 20 million / inch |

| Miscalculation rate (0201) | ≤0.01% |

| Accuracy | 99.99% (0201 as an example) |

| Minimum part size that can be detected | 01005 |

| Record keeping requirements | Save by day, no capacity limit, TXT.CSV.XLS |

| Operating system | WINDOWS 11 |

| Power supply | AC110-220V50-60HZ |

| Power | 1200W |

| Radiation safety test | <1 uSV/H |

| Repeatability test | ≥2.0sigma |

| CYCLE TIME | ≤10s / time |

| Material counting speed | 6-10 S / 4 reels (CHIP 0201) |

| Max diameter of the material reel | 430mm(4-17INCH) |

| Max height of the material reel | 1-92mm |

| Max weight of the material reel | ≤10kg |

| Machine size | 730*1460*1960mm(L*W*H) |

| Machine size (including printer) | 950*1460*1960mm(L*W*H) |

| Machine weight | 450kg |

| Stage movement mode | Auto-mode |

| CE Certificate | Yes: STE23112103S |

| State immunity | Yes |

| Radiation Safety Permit | Yes: Guangdong Environmental Radiation Safety Permit [B0640] |

Related products

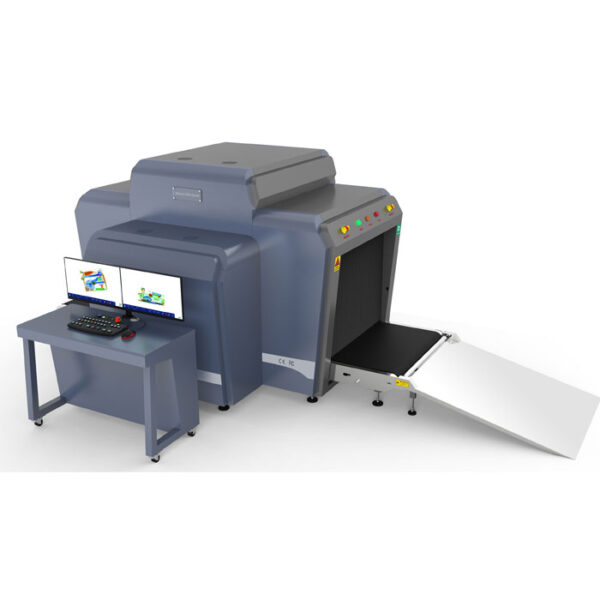

MTC-64XPRO x-ray luggage scanner is an extremely effective device in checking and detecting items and goods inside luggage

The Matrixcope MTC-XR108D baggage x-ray machine is designed to screen baggage, mail and parcels at the entrance of sensitive areas, ensuring a high level of safety.

Matrixcope MTC-XR500P security baggage scanner is a type of mobile security inspection equipment, which uses X-rays to penetrate and inspect luggage and goods without the need to inspect packaging.