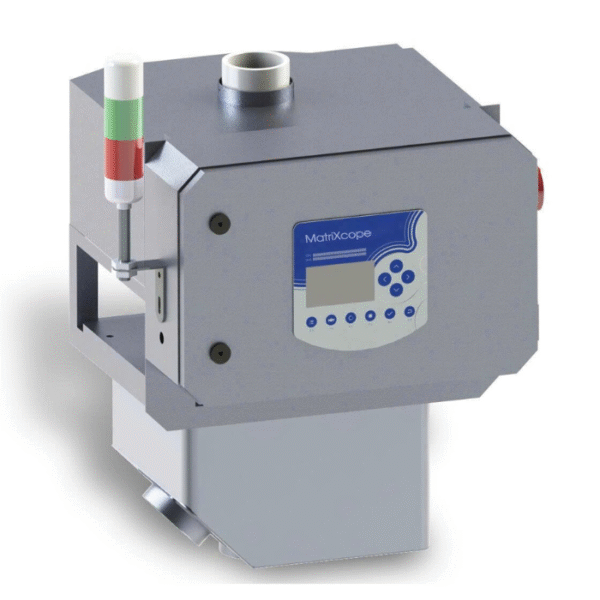

Belt Conveyor Metal Detectors Matrixcope MTC-9005XPRO

The Matrixcope MTC-9005XPRO conveyor metal detector is designed to inspect products for metal contamination in the food, plastic, and packaging industries.

Product Documents

Downloads

Overview of the Matrixcope MTC-9005XPRO Conveyor Metal Detector

The Matrixcope MTC-9005XPRO conveyor metal detector is designed to inspect products for metal contamination in the food, plastic, and packaging industries. The product can be purchased as a detector head integrated into a production or packaging line. Once installed, it reliably protects both consumers and machinery from metallic impurities, while helping manufacturers achieve compliance with standards such as HACCP, GMP, FDA, and ISO, improve product quality, and safeguard their brand reputation.

Key Features of the Matrixcope MTC-9005XPRO Conveyor Metal Detector

-

Can be integrated with existing conveyor systems.

-

Simple user interface provides real-time machine status.

-

Multi-product memory for quick product changeover and storage of up to 207 product data entries.

-

Intermediate frequency technology offers the best balance between detection performance and cost.

-

A 7″ touchscreen display is standard on all MTC-9005XPRO models, enhancing usability compared to previous generations.

-

Auto-learn function delivers excellent detection sensitivity right out of the box and ensures longer uptime than ever before.

-

USB function (optional): Export detection data via USB port.

Exclusive Distributor of the Matrixcope MTC-9005XPRO Conveyor Metal Detector

The Matrixcope MTC-9005XPRO conveyor metal detector series offers advanced detection capabilities for the food, plastic, and packaging industries, ensuring compliance with international safety standards. With features such as a user-friendly interface, auto-learn function, and flexible integration options, these detectors enhance both product quality and operational efficiency.

Technical Specifications of the Matrixcope MTC-9005XPRO Conveyor Metal Detector

| Specification | Details |

|---|---|

| Construction Material | Stainless Steel 304 |

| Memory Function | Stores up to 207 product parameters |

| Control Panel Languages | English, Spanish, Korean, Chinese |

| Auto-Learn Function | Yes |

| Operating Frequency | 100 to 200 kHz |

| Display | 7” full-color touchscreen |

| USB Capability | Optional |

| Conveyor Belt Material | Standard: White PVC (PU material optional) |

| Conveyor Length | Standard: 1400mm (Customizable) |

| Conveyor Speed | Standard: Fixed speed 24m/min (Adjustable speed optional) |

| Conveyor Height from Ground | Standard: 680mm ± 30mm (Customizable) |

| Conveyor Direction | Standard: Left to right (operator facing the control panel) |

| Motor Power | Standard: 120W (Options: 200W, 400W) |

| Load Capacity | Standard: 5 kg (Options: 10kg – 100kg) |

| Alarm Method | Audio and red light alarm; conveyor automatically stops |

| Emergency Stop Button | Included |

| Operating Temperature | -5℃ to 40℃ (23℉ to 104℉) |

| Automatic Reject System | Optional (Please refer to options below) |

| Humidity | Relative humidity below 90% (Non-condensing) |

| Power Supply | AC 110–380V (50/60Hz) |

Related products

The MatriXcope MTC-9080XPRO metal detector accurately detects foreign objects such as metals (ferrous, non-ferrous, stainless steel), ceramics, stones, and glass in bottled, canned, or jarred products—even when the packaging is metal-coated.

MTC-8001XPRO Automatic Conveyor Needle Detector is one of basic models of our company. It is good for clothing,shoes,toys,textiles,knitwear and so on. It is fit to any enterprises which need detect broken needle or ferromagnetic metal.

The MatriXcope MTC-9050XPRO metal detector accurately detects foreign objects such as metals (ferrous, non-ferrous, stainless steel), ceramics, stones, and glass in bottled, canned, or jarred products—even when the packaging is metal-coated.