High Configuration X-ray Inspection System for Bulk Products MTC-YCT-5800HA

High-performance X-ray inspection system for bulk products MTC-YCT-5800HA with advanced sensitivity; performance may vary by product and conditions.

Product Documents

Downloads

Overview of high configuration X-ray inspection system for bulk products MTC-YCT-5800HA

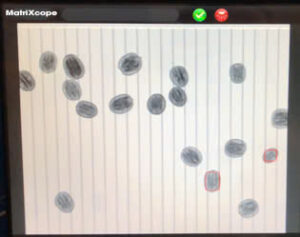

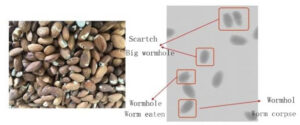

In high-throughput production environments, precision and adaptability are key in foreign object detection. The MTC-YCT-5800HA from MATRIXCOPE is a high-configuration X-ray inspection system engineered specifically for bulk products. Designed with advanced detection algorithms and robust hardware architecture, this system provides outstanding sensitivity under controlled conditions—tested using a single sample on the conveyor belt.

Technical specifications of high configuration X-ray inspection system for bulk products MTC-YCT-5800HA

| Best Inspection Ability | 0.2*0.2*0.2mm(SUS304 ball)

0.3*2mm( SUS wire) 0.8mm (Glass Ball) 0.8 mm(Ceramic) 1.5-2.0 mm (bone, gravel) |

| X-ray tube | MAX.500W/80kV (Beryllium widnow) |

| Detector | 0.4mm TDI Detector |

| Tunnel Height | 100mm |

| Tunnel Width | 800mm |

| Conveyor Speed | Max 120m/min |

| Estimated Max Capacity | 3-4 tons per hour |

| Conveyor Height | 900+100 mm |

| Working Direction | From left to right |

| Screen | Full-color TFT 15″ Touch Screen |

| O/S | Windows 7/10 |

| Connectivity | LAN port, USB port |

| Product Management | Complete product log |

| Parameter Adjustment | Auto learning/Manual setting |

| Image Management | Auto image save/print/analyses |

| Power Supply | 220V, AC, 50/60Hz |

| Body Material | SUS304 |

| Purification | Easy to wash |

| Cooling method | Air conditioned cooling |

| Operation temperature | 0-40°C |

| Operation humidity | 30-90% |

| X-ray emissions | < 1microsievert per hour |

| X-ray protection | Lead/Lead-free protective curtain |

| Rejector | 96 tunnel air jet rejector |

The specified technical sensitivity is based on ideal test conditions and may vary depending on product characteristics and operating environment. Nonetheless, the MTC-YCT-5800HA remains a reliable and high-performance solution for manufacturers seeking enhanced safety and efficiency. Explore more at https://matrixcope.com.

Technical specifications of high configuration X-ray inspection system for bulk products MTC-YCT-5800HA

| Best Inspection Ability | 0.2*0.2*0.2mm(SUS304 ball)

0.3*2mm( SUS wire) 0.8mm (Glass Ball) 0.8 mm(Ceramic) 1.5-2.0 mm (bone, gravel) |

| X-ray tube | MAX.500W/80kV (Beryllium widnow) |

| Detector | 0.4mm TDI Detector |

| Tunnel Height | 100mm |

| Tunnel Width | 800mm |

| Conveyor Speed | Max 120m/min |

| Estimated Max Capacity | 3-4 tons per hour |

| Conveyor Height | 900+100 mm |

| Working Direction | From left to right |

| Screen | Full-color TFT 15″ Touch Screen |

| O/S | Windows 7/10 |

| Connectivity | LAN port, USB port |

| Product Management | Complete product log |

| Parameter Adjustment | Auto learning/Manual setting |

| Image Management | Auto image save/print/analyses |

| Power Supply | 220V, AC, 50/60Hz |

| Body Material | SUS304 |

| Purification | Easy to wash |

| Cooling method | Air conditioned cooling |

| Operation temperature | 0-40°C |

| Operation humidity | 30-90% |

| X-ray emissions | < 1microsievert per hour |

| X-ray protection | Lead/Lead-free protective curtain |

| Rejector | 96 tunnel air jet rejector |

Related products

The Matrixcope MTC-76XPRO is a state-of-the-art X-ray inspection system designed specifically for detecting fish bones and metallic contaminants in processed fish meat.

Features of MatriXcope MTC-XR65 Baggage Scanning X-ray Machine High-end MatriXcope MTC-XR65 baggage x-ray machine, high penetration, sharp images, penetration of steel sheets up to 32mm, suitable for many environments and high requirements. Multilingual operation Automatic built in test and self diagnosis Secure access Key Threat alert and material classification Auto archiving Energy saving design One...

The Matrixcope MTC-XR1010D is a specialized luggage scanning X-ray machine designed to enhance airport security by providing high-resolution images of the contents of passengers' luggage.