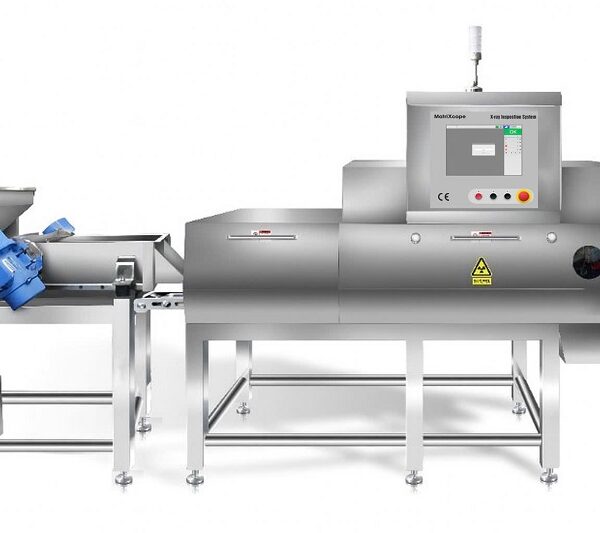

High Configuration X-ray Inspection System for Bulk Products Before Packaging MTC-8100XPRO

MTC-8100XPRO is a high-configuration X-ray inspection system for bulk products, offering fast, accurate detection, improved efficiency, and reliable food safety assurance.

Product Documents

Downloads

Overview of high configuration x-ray inspection system for bulk products before packaging MTC-8100XPRO

In modern industrial production lines, bulk product inspection requires high-speed operation, accurate detection, and effective foreign object rejection. Addressing these critical demands, MATRIXCOPE introduces the high configuration x-ray inspection system for bulk products before packaging Matrixcope MTC-8100XPRO. Designed with an extended drive conveyor for smooth and stable product flow, enhanced CPU processing capability, and a high-capacity X-ray generator, the system delivers optimized sensitivity and outstanding throughput performance.

Technical specifications of high configuration x-ray inspection system for bulk products before packaging Matrixcope MTC-8100XPRO

|

PHYSICAL SPECIFICATIONS |

|

| Best Inspection Ability | 0.1mm(SUS304 ball) 0.04*5mm( SUS wire)

0.8mm (Glass Ball) 0.8 mm(Ceramic) |

| X-ray tube | MAX.500W/80kV (Beryllium window) |

| Tunnel Height | 100mm |

| Tunnel Width | 800mm |

| Conveyor Speed | Max 90m/min |

| Estimated Max Capacity | 16-20 tons per hour (Depending on the product) |

| Conveyor Height | 900+100 mm |

| Working Direction | From left to right |

| Screen | Full-color TFT 15″ Touch Screen |

| O/S | Windows 7 & 10 |

| Connectivity | LAN port, USB port |

| Product Management | Complete product log |

| Parameter Adjustment | Auto learning/Manual setting |

| Image Management | Auto image save/print/analyses |

| Power Supply | 220V, AC, 50/60Hz |

| Body Material | SUS304 |

| Purification | Easy to wash |

| Cooling method | Air conditioned cooling |

| Operation temperature | 0-40°C |

| Operation humidity | 30-90% |

| X-ray emissions | < 1microsievert per hour |

| X-ray protection | Lead/Lead-free protective curtain |

| Rejector | 160 tunnel air jet rejector |

With its advanced detection accuracy, robust engineering, and intelligent automation, the Matrixcope MTC-8100XPRO stands out as a dependable solution for modern bulk product inspection. By seamlessly combining high speed, precise detection, and operational safety, this high-configuration X-ray system not only improves product quality and production efficiency but also supports manufacturers in upholding the highest standards of food safety and consumer confidence.

|

PHYSICAL SPECIFICATIONS |

|

| Best Inspection Ability | 0.1mm(SUS304 ball) 0.04*5mm( SUS wire)

0.8mm (Glass Ball) 0.8 mm(Ceramic) |

| X-ray tube | MAX.500W/80kV (Beryllium window) |

| Tunnel Height | 100mm |

| Tunnel Width | 800mm |

| Conveyor Speed | Max 90m/min |

| Estimated Max Capacity | 16-20 tons per hour (Depending on the product) |

| Conveyor Height | 900+100 mm |

| Working Direction | From left to right |

| Screen | Full-color TFT 15″ Touch Screen |

| O/S | Windows 7 & 10 |

| Connectivity | LAN port, USB port |

| Product Management | Complete product log |

| Parameter Adjustment | Auto learning/Manual setting |

| Image Management | Auto image save/print/analyses |

| Power Supply | 220V, AC, 50/60Hz |

| Body Material | SUS304 |

| Purification | Easy to wash |

| Cooling method | Air conditioned cooling |

| Operation temperature | 0-40°C |

| Operation humidity | 30-90% |

| X-ray emissions | < 1microsievert per hour |

| X-ray protection | Lead/Lead-free protective curtain |

| Rejector | 160 tunnel air jet rejector |

Related products

High-performance X-ray inspection system for bulk products MTC-YCT-5800HA with advanced sensitivity; performance may vary by product and conditions.

MatriXcope MTC-XR1518D baggage scanner detects weapons, explosives, drugs, money, gold, or detects inorganic and organic substances... The machine is used in the fields of security control at: Airports, border gates, government offices, embassies...

High-speed X-ray MTC-YCT-5191HA inspection system with enhanced sensitivity, 48-air jet rejector, and 120m/min belt — ideal for bulk product quality control.