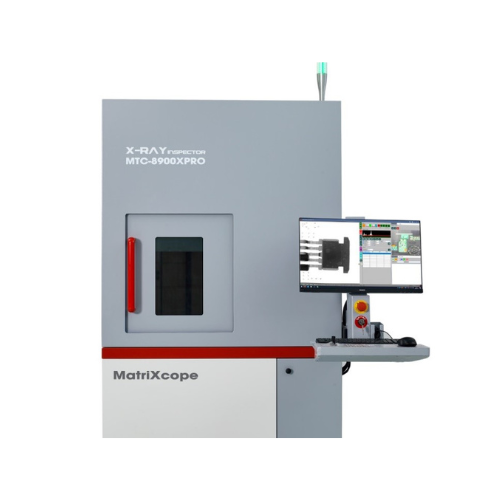

Universal X-RAY Equipment Matrixcope MTC-8900XPRO

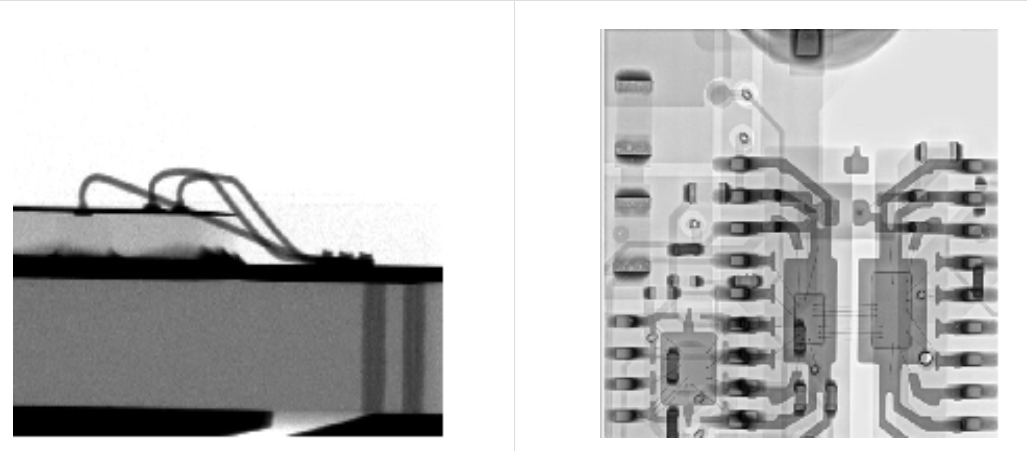

The Matrixcope MTC-8900XPRO electronic semiconductor inspection equipment can be used to detect integrated circuit chip semiconductors with high precision testing

Product Documents

Downloads

Overview of universal x-ray equipment Matrixcope MTC-8900XPRO

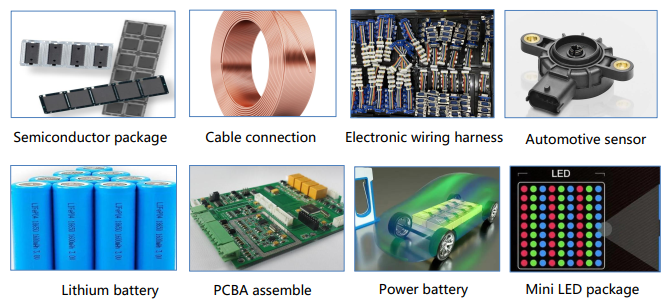

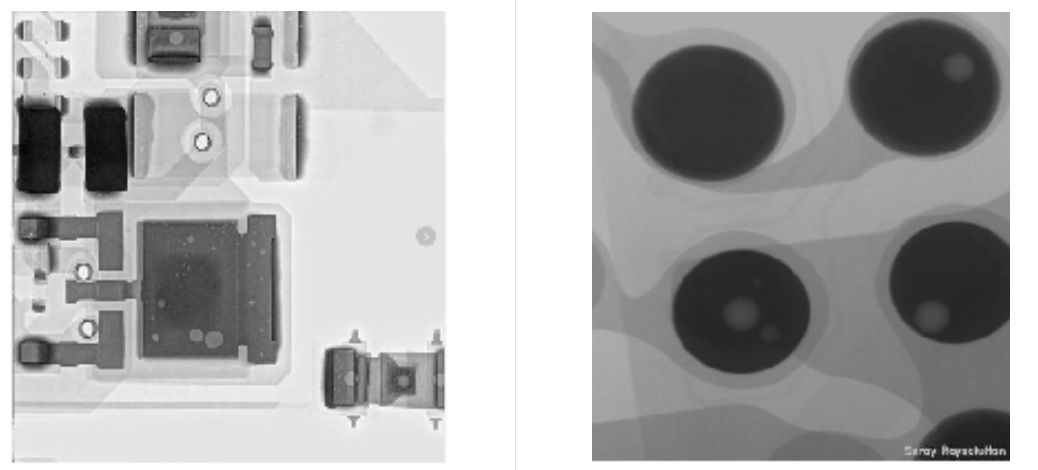

The Matrixcope MTC-8900XPRO electronic semiconductor inspection equipment can be used to detect integrated circuit chip semiconductors with high precision testing, such as BGA, IGBT, flip chip and PCBA module welding, LED, photovoltaic etc. Widely used in industrial manufacturing field, such as automobile parts, casting testing, quality testing for pressure vessel and pipe welding; Can detect defects of various types of battery, such as power battery, cylinder, soft packaging, square battery and laminated board.

Application:

- Semiconductor package 4. Electronic wire harness

- Lithium battery 5. PCBA assembly

- Automotive sensors 6. Mini LED package

Specifications of universal x-ray equipment Matrixcope MTC-8900XPRO

|

PHYSICAL SPECIFICATIONS |

|

| X-Ray tube type | Enclosed type |

| Spatial resolutiaon | 3um |

| Light tube voltage | 130KV (Optional 100KV、90KV) |

| Light tube current | 300uA |

| Magnification | Optical magnification 450X, system magnification 2000X |

| Digital flat panel detector resolution | 1536*1536 px |

| Digital flat panel detector density value | 16bit (655) |

| Image speed | 20 (FPS) |

| Detector rotation angle | 60° |

| Stage size | 540*540mm |

| Sensing range | 510*510mm |

| Load-bearing | ≤10kg |

| Examination range | 0.02-45cm2 |

| Machine size | 1100*1360*1950mm(L*W*H) |

| Machine weight | 1050KG |

| operating system | WINDOWS 10 |

| Power supply/power | AC110-220V 50-60HZ 1200W |

| Radiation safety test | <1 uSV/H |

| Detector rotation angle | Automatic / manual |

| CE Certificate | Yes: STE23112101S |

| State immunity | Yes |

Functional Advantage:

| Function | Advantage |

| CNC program: Automatically detect batch of

different samples’ locations |

Automatically ON / OFF X-Ray tubes detect

batch of samples |

| Array function: Automatically detect batch of

samples with fixed position and same spacing |

With high-stability and high-precision X-Ray

tube |

| Bubble measurement: measure the bubble size,

cavity rate, tin climbing height with one button |

High definition digital X-Ray detector |

| Length and width measurement: the length

and width of the measured inspection area |

The stage can place a large number of samples

of various sizes |

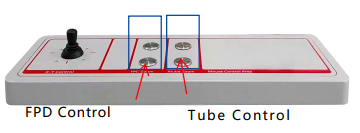

| Visual navigation interface: accurate positioning,

accurate displacement from x – y with joystick |

The stage can do 360° rotation to detect

sample |

| Simulated color: to better observe and

detect the image |

Can do 60° tilt observations |

High-end Configuration

Engineered for versatility and precision, the MTC-8900XPRO is an advanced inspection solution trusted across a wide range of industries — from semiconductor and electronics manufacturing to automotive, energy, and industrial quality assurance. Whether you’re inspecting BGA, IGBT, flip chips, LED modules, or battery components, the MTC-8900XPRO delivers uncompromising accuracy and reliability.

Reach out to the official Matrixcope distributor today for expert consultation and pricing tailored to your needs.

? Explore the full range of Matrixcope solutions at: https://matrixcope.com/

Specifications of universal x-ray equipment Matrixcope MTC-8900XPRO

|

PHYSICAL SPECIFICATIONS |

|

| X-Ray tube type | Enclosed type |

| Spatial resolutiaon | 3um |

| Light tube voltage | 130KV (Optional 100KV、90KV) |

| Light tube current | 300uA |

| Magnification | Optical magnification 450X, system magnification 2000X |

| Digital flat panel detector resolution | 1536*1536 px |

| Digital flat panel detector density value | 16bit (655) |

| Image speed | 20 (FPS) |

| Detector rotation angle | 60° |

| Stage size | 540*540mm |

| Sensing range | 510*510mm |

| Load-bearing | ≤10kg |

| Examination range | 0.02-45cm2 |

| Machine size | 1100*1360*1950mm(L*W*H) |

| Machine weight | 1050KG |

| operating system | WINDOWS 10 |

| Power supply/power | AC110-220V 50-60HZ 1200W |

| Radiation safety test | <1 uSV/H |

| Detector rotation angle | Automatic / manual |

| CE Certificate | Yes: STE23112101S |

| State immunity | Yes |

Related products

Features of MatriXcope MTC-XR65 Baggage Scanning X-ray Machine High-end MatriXcope MTC-XR65 baggage x-ray machine, high penetration, sharp images, penetration of steel sheets up to 32mm, suitable for many environments and high requirements. Multilingual operation Automatic built in test and self diagnosis Secure access Key Threat alert and material classification Auto archiving Energy saving design One...

In today's security-conscious world, the need for efficient and reliable baggage scanners is paramount. Let's delve into the features of an advanced X-ray baggage scanner that combines cutting-edge technology with safety and environmental considerations:

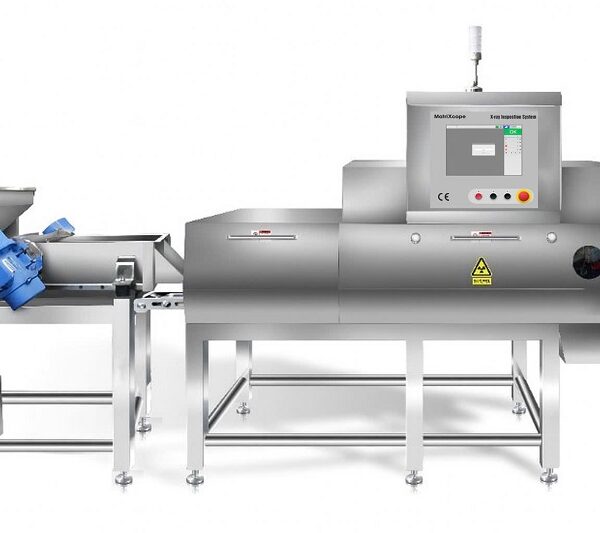

High-performance X-ray inspection system for bulk products MTC-YCT-5800HA with advanced sensitivity; performance may vary by product and conditions.