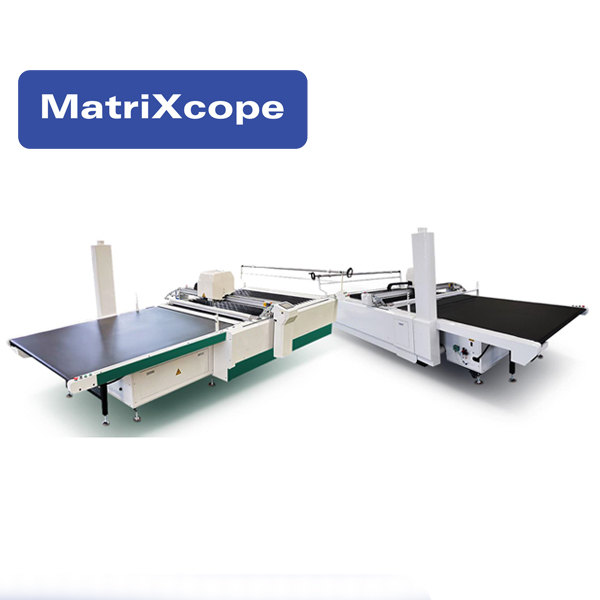

Matrixcope CNC Multi-Layer Cutting Machine MTC-HDF2638

The Matrixcope CNC Multi-Layer Cutting Machine MTC-HDF2638 is a next-generation automated cutting solution designed to maximize efficiency and accuracy for garment factories, upholstery makers, and industrial textile operations

Product Documents

Downloads

Overview of Matrixcope CNC Multi-Layer Cutting Machine MTC-HDF2638

The Matrixcope CNC Multi-Layer Cutting Machine MTC-HDF2638 is a next-generation automated cutting solution designed to maximize efficiency and accuracy for garment factories, upholstery makers, and industrial textile operations. By combining computer-controlled technology with intuitive operation, this machine delivers high-speed, precision cutting while reducing material waste and labor costs.

Outstanding features of Matrixcope CNC Multi-Layer Cutting Machine MTC-HDF2638

Exceptional Cutting Accuracy

The MTC-HDF2638 ensures each piece is cut with high precision, allowing sewing teams to work directly without extra trimming. This significantly boosts overall production efficiency.

Zero-Distance Cutting to Save Materials

Advanced engineering enables zero-gap cutting, helping manufacturers minimize raw material consumption and reduce production expenses.

Multi-Source Software Compatibility

The integrated control software supports multiple data formats and can directly import popular clothing design and typesetting files, making it easy to connect with existing design workflows.

Seamless Motion Control

Unique algorithms and motion technology create smooth transitions between straight lines and arcs, ensuring a flawless cut every time.

Automatic Sharpening Technology

Built-in sharpening adapts to fabric characteristics, extending the cutting knife’s service life and minimizing downtime.

Simple, Automated Operation

The MTC-HDF2638 eliminates the need for paper templates. With computer-controlled automation, it replaces a large number of manual cutters, perfect for mass production.

| Parameter | MTC-HDF2836 |

|---|---|

| Clipping Height | 1 – 11 cm |

| Effective Cropping Width | 1700 mm |

| Effective Cutting Length | Automatic feeding, unlimited length |

| Automatic Spreading Length | 16.8 m spreading table (total working length 24 m) |

| Land Size | 2600 mm (W) × 3500 mm (L) × 1600 mm (H) |

| Knife Transport Method | Reciprocating vibrating knife transport |

| Cutting Speed | 0 – 60 m/min |

| Cutting Knife Grinding | Double wheel counter-rotating grinding |

| Adsorption Method | Frequency conversion vacuum constant pressure control mode |

| Safety Devices | Automatic induction |

| Power Supply | Three-phase AC380 V / 50 Hz / 25 kW |

| Operate Computer | Ordinary computer, Windows 7 |

| Operation Panel | Touch control panel |

| Clipping Parameters | Input LAN, USB |

| Device Weight | About 4500 kg |

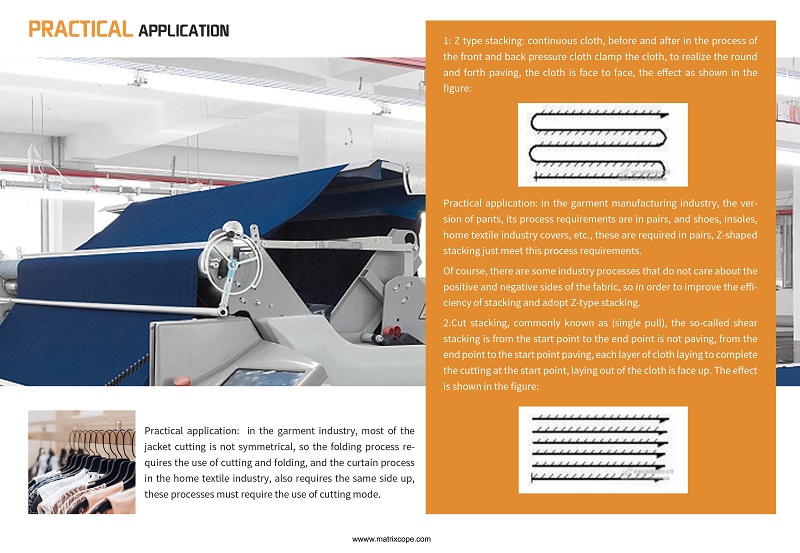

| Standard Fitting Features | 1. Automatic adjustment of cutting speed 2. Secondary compensation for cutting vacuum 3. Inductive safety protection device 4. Automatic feeding platform 5. Air flotation workbench × 14 sheets 6. Automatic spreading machine × 1 (single pull, double pull, cutting, automatic edge alignment, etc.) |

| Other Functions | Mobile cutting device, automatic feeding device, pattern scanning, adsorption bed |

| Operating System Capabilities | Supports overall rotation of the nesting chart; knife-edge conversion; single-piece recutting; one-key deletion of overlapping areas (removal of repeated lines); residual cloth cutting |

| Main Machines & Accessories | 1. Automatic multi-layer cutting bed 2. Automatic cloth spreading machine 3. Air flotation table |

Related products

The Matrixcope MTC-D2043 is a premium automatic bollard engineered to deliver robust protection against unauthorized vehicle access and intentional ramming attacks.

MTC-HDF3141 is an advanced automatic cutting solution designed to meet the demands of garment factories, upholstery makers, and industrial fabric producers

MTC-HDF3441 is a professional-grade automatic cutter engineered for garment factories, upholstery workshops, and industrial textile producers.